Major milestones in the development of the ``MZOR'' plant

History of creation and development of the ``MZOR'' plant

Scientific, design, technological and production components of the full cycle allow MZOR OJSC to offer the Customer not just machine tools, but complexes, which include: machine, fixture, tool, technological and software, as well as engineering and service support of the supplied equipment.

0000The company’s products meet international quality standards, which is confirmed by the certified and functioning integrated quality management system, environmental management system and labor protection management system developed by MZOR specialists.

Machine tools produced by MZOR OJSC are successfully operated at the largest enterprises of various industries both in the Republic of Belarus and abroad.

Along with manufacturing of metal-cutting machine tools, the company is engaged in overhaul and modernization of technological equipment both of its own production and other manufacturers, including foreign ones; provides metalworking services. JSC “MZOR” is a reliable partner in all directions of its activity. We are open to any forms of mutually beneficial cooperation.

1908 year

The first official metallurgical enterprise was registered in Minsk – “Cast Iron Foundry and Metalworking Plant” with the name of –

“Giant.”

1911 year

Electricity was installed at the plant, which was the basis for renaming the enterprise to the Energia plant. It had already employed 63 people.

1918 year

After the October Revolution, the Energia plant was nationalized and transferred to the ownership of the socialist state. “Energia” – the first Soviet machine-building and iron foundry in Belarus.

1921 year

The plant set up production of sophisticated agricultural equipment. According to the production report for 1921-1922, the “Energia” plant produced 1332 plows, 161 straw cutters, and 2313 pieces of various castings.

1926-1928 year

The date of birth of major machine tool and machine building in our country. The Energia plant produced a prototype of the first lathe. The plant is increasing production volumes, 15 lathes and 200 drilling machines, 70 stone crushers, 100 gravel-sorting machines have been produced.

1929 year

The Soviet government awards the Energia plant with the Order of the Red Banner of Labor. The plant employs 400 people. The plant increases production volumes for the year, 21 lathes and 354 drilling (SV-25) machines were manufactured.

1931 year

On February 16, the Energia plant was renamed to the K.E. Plant. Voroshilova.

1933-1934 year

In April the enterprise was visited by the Chairman of the Presidium of the Supreme Soviet of the USSR M.I.Kalinin and the plant started working on the project of one of the largest longitudinal planing machines, which had a table size of 820X2306 mm. and a weight of about 9 tons. The history of the world machine-tool building has never known its analogues.

In 1934 it was assembled and put into serial production Longitudinal planer with table size 820X2306 mm.

1944 year

The first product manufactured by the plant after the liberation of Minsk was a tank column of 10 restored armored vehicles. In November the second tank column was ready, in December the third!

1948 year

Minsk Machine-Tool Plant named after K.E. Voroshilov manufactures the first prototype of the modern slitting and planing machine model 7231A. The machine was designed for rough and finish planing of parts made of cast iron, steel and non-ferrous metals. It has found very wide application in various branches of metalworking industry.

1949 - 1950 year

The plant is building up its power. The foundations of a new foundry were laid, and a basic section of Mechanical Assembly Shop No. 1 was created. Design work on six models of longitudinal planing machines (7231, 7134, 7242A, 7242B, 7142A) was completed.

By the end of the five-year plan the plant produced 1095 longitudinal planing machines of different models for the national economy of the country. At the same time, design work was completed on the creation of edging machines (7C2, MC-7, 7806), hydroficated chiseling machine (745), electrified chiseling machine (745M), deburring and trimming machine (2C-1), machine for removing seams on the ends of welded pipes (MC-11) and others.

1959 year

Production of new models of metal-cutting machine tools and modernization of existing ones is expanding. By machine groups that have already been produced are 7243, 7243A, 7233, 7133. Brand new products – longitudinal planing machines models 7208, 7210, 7212, 7216, 7108, 7110, 7112, 7116; longitudinal milling machines 6606, 6608, 6610, 6612, 6306, 6308, 6310, 6312 and longitudinal grinding machines 3508, 3510, 3512, 3508B, 3510B, 3512B). The design features of the listed products provided higher precision, cleaner and more productive machining, a wide range of table speeds, rigidity of the slide group, infinitely variable feed rate control, remote control and safety system. At that time they could handle parts weighing from 10 kilograms to 50 tons!

1961 year

On November 1, the plant named after C.E. Voroshilov plant was renamed into the October Revolution plant

1965 year

The plant increases the output of gross and marketable products in the new five-year period in 2.3 times, machine tools – in 2.2 times, and special machine tools – in 3 times, the output of casting with the use of quick-drying mixtures – in 2 times, sand-compounding of molds – in 10 times.

1975 year

The designers of the plant are developing completely new products, which the machine tool industry has never known before: longitudinal grinding machine model ZM508, combined planer and milling machine model 7216G, balancing machine with vertical axis of rotation model 9766. To many regions of the country were sent combined planing and milling machines model 7212G, chiseling machines model 7410, the fame about the quality of which becomes widely known in the USSR and far beyond its borders. Two models of longitudinal planing machines (7212 and 7216) received the “USSR Quality Mark”.

1980–1981 year

The plant’s engineering staff and workers are developing in many areas. For example, for a customer from the Ulyanovsk aircraft plant, the design department was developing a special machine designed for mounting slipway-assembly tooling (model MC636F2). The company’s employees also worked on the creation of two industrial robots for the Minsk branch of Orgstankinprom. We persistently overcame difficulties in the development of ball pairs VPSH-52 and VPSH-53 for the machine model MS625MF4 for SPO “Progress” of Kimry. A separate group carried out work on control and sorting balancing machines of model MS9131 included in the production plan. I also had to do something quite unusual: creating a milling and boring machine with a matrix logic device.

1982 year

A machine designed for dynamic balancing of rotors has been developed (model 9719B). Production of five longitudinal multi-operating CNC milling and boring machines model 6M610FZ began. A CNC multi-tool machining center for machining rotor half-coils of turbine generators with a capacity of 1 million was put into operation. kilowatts and up. Such unique products were not yet known in the Union!

1985 year

A number of modernized longitudinal planing machines models 7A110, 7A21O, 7A112, 7A212, 7A116, 7A216, as well as a heavy CNC milling and boring machine for processing parts weighing up to 50 tons (with table width up to 2500mm) were put into production.

1987 year

The Minsk Machine-Tool Production Association named after the October Revolution becomes directly subordinate to the Main Directorate for Production of Special Machine Tools and Automatic Lines (Glavstankoliniya). The association was on an economic basis and was a legal entity. It had the right to produce the goods necessary for the realization of the tasks assigned to it throughout the territory of the Soviet Union. Thanks to such reorganization it was possible to launch the machine model 9718-22, to make the machine model 6M612F11-23, as well as to “swing” to the distant future and start mastering the machine tools of models 6B610F10, 6B610F13, 6B612F10, 6B612F13, 6B612F10, 6B612F13, 6B616F10, 6B616F13, 6B610MF4, 6B612MF4, 6B616MF4,7B210, 7B110, 7B212, 7B216, 7B314, 7B410, 7B210GF10. 7B212GF10, 7B216GF1O and others

1989 year

Longitudinal milling and boring machines 6M612F11, 6M616F11, 6M612F4, 6M616F4 have been put into production. In the 80s Minsk plant in several years was able to prepare and implement more than 20 new models of unique multidisciplinary machine tools, to hand over the machining center and to find the key to the solution of a new task – to provide the aviation industry with new CNC longitudinal milling and boring machines.

1999 year

On December 28, the company was called – the production republican unitary enterprise “MZOR”.

2002 year

On the day of liberation of Belarus from Nazi invaders, the President of the Republic of Belarus, A.G. Lukashenko. Lukashenko congratulated the staff of MZOR on the holiday: “Today you make a significant contribution to the stable development and strengthening of socio-economic, scientific, technical and cultural potential of our republic. High professionalism and diligence of the employees of your organization are the guarantee of further successes and a worthy example for other labor collectives”.

2006 year

Completely new developments came off the production lines: a milling and boring machine designed for machining of shackles, crosses, frame rails and other parts of switches. High precision, adaptation to temperature fluctuations and structural rigidity – this is how the creators characterize the machine. The second development can be called pre-resonant balancing machine, designed to determine the initial unbalance of rigid inter-support and cantilever rotors, provides the selection of the optimal speed during balancing, which is induced on the measuring panel. Modernized special lathe and carousel machine with CNC is designed for machining of solid-rolled railway wheels and other parts of complex shape of “disk” type. The list of metal-cutting and balancing equipment includes: horizontal milling and boring machine model MPS6401MF4-04, vertical milling machine with cross table, CNC and ASI model MS6590PMF4 longitudinal milling and boring machine with CNC model MS625F4U-08, multifunctional drilling, milling and boring machine model MS21G40MF4-08 and many others.

2011 year

MZOR OJSC was reorganized into an open joint-stock company with 100% state ownership.

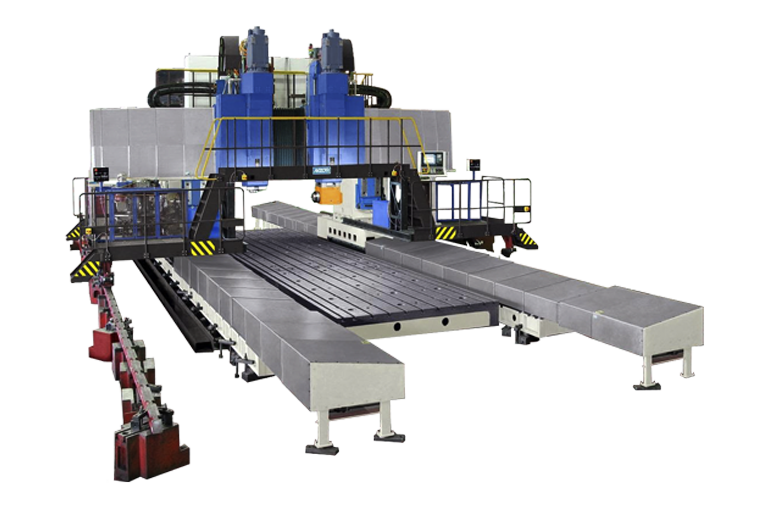

2012 year

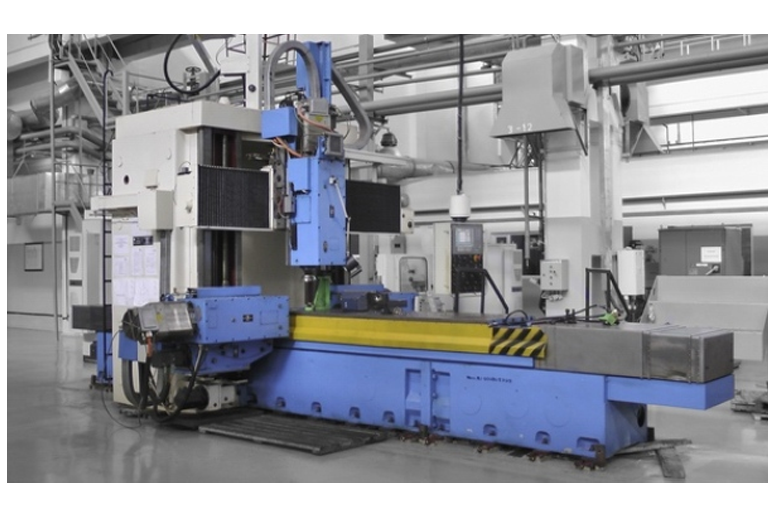

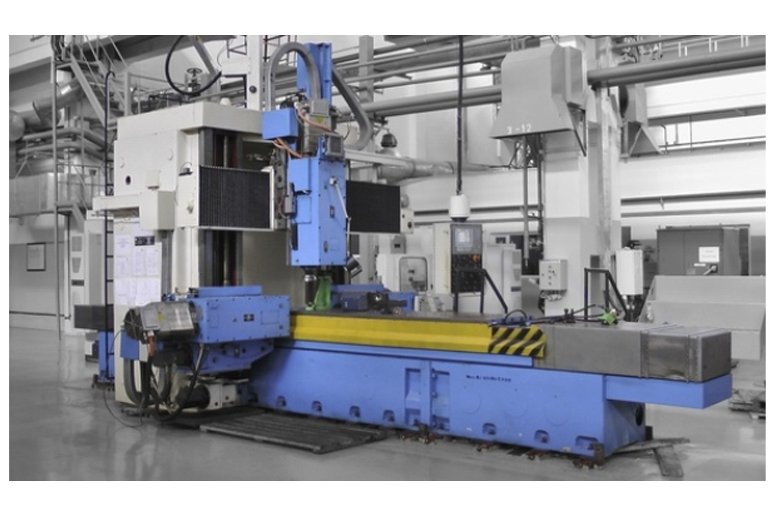

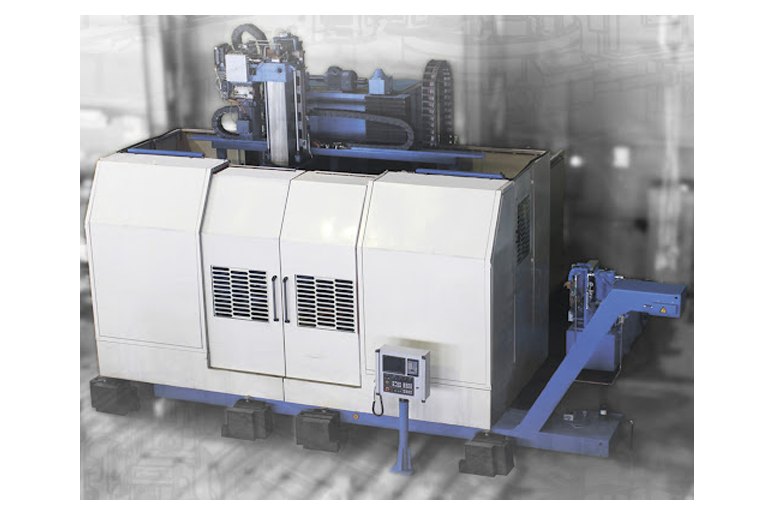

Holding “Belstankoinstrument” was established and the enterprise received a new name JSC “MZOR” – Managing Company of Holding “Belstankoinstrument”. The holding includes 16 enterprises of the Ministry of Industry of the Republic of Belarus – manufacturers of machine-tool industry with a total number of about 9,600 people. During this period the production of a special longitudinal drilling and milling machine with CNC and automatic tool changer (ATCM) mod. MS21G25MF4, which allowed to expand the range of produced machines with longitudinally movable gantry with a wide range of coordinate movement lengths: gantry – from 5 000 to 15 000 mm, headstock – from 1 500 to 4 500 mm, slider – from 800 to 1 500 mm. For the first time in the Republic of Belarus the production of special horizontal CNC milling and boring machines with moving stand and UASI mod. MS200MF4 is a new type of horizontal boring machine with a movable stand, which allows machining large-sized parts with accuracy corresponding to the 7th qualification and hard-to-reach internal surfaces.

2016 year

A decision was made to accept the shares of the Belstankoinstrument holding companies into the Republican ownership free of charge. The enterprise is returned to the name of JSC “MZOR”. In this year a special technological complex for processing of large-size products from composite materials model MSP6403MF4-10P2, and also for the first time the design documentation of the lathe-carousel machining center with CNC milling function and UASI model MSTK16MF4 were produced.

2019 year

The prototype of turning and carousel machining center with CNC milling function and UASI model MSTK16MF4 was produced.

2022 year

Igor Yakutsenya was appointed director of the company in October. By Order of the Ministry of Industry of the Republic of Belarus No. 357 dated October 13, 2022 “On increasing the authorized capital and amending the Articles of Association of JSC BELAZ – Managing Company of BELAZ-HOLDING Holding” it was decided to include MZOR JSC into the holding company as a subsidiary. After corporate procedures, the Ministry of Antimonopoly Regulation and Trade gave its consent to the inclusion of MZOR OJSC in the holding company from December 1, 2022.

OUR CONTACTS

-

Минск, ул. Ленина, 46

Минск, ул. Ленина, 46

-

+375(17) 224 59 22

+375(17) 224 59 22

-

mail@mzor.by

mail@mzor.by

CONTACT FORM

If you have any questions, you can contact us using the contact form below.