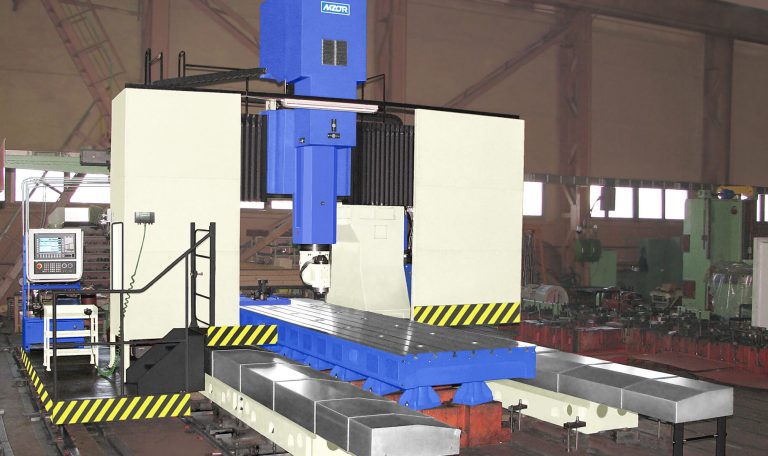

0000Special longitudinal drilling and milling machine with computer numerical control (CNC) and automatic tool changer (ATC). mod. МС21Г25МФ4.

0000Special longitudinal drilling and milling machine with computer numerical control (CNC) and automatic tool changer (ATC). mod. МС21Г25МФ4.

0000The machine is designed for complex machining of large-sized body parts made of ferrous and non-ferrous metals by milling, drilling, boring and threading methods.

Technical characteristics of special longitudinal drilling and milling machine mod. МС21G25МF4

| Name of parameters | Significance |

| Dimensions of the working surface of the table, mm:

– width – length |

2 500 6 000 |

| Distance between gantry posts, mm | 3 500 |

| Spindle speed limits, min-1 | 10…3000 |

| Main motion drive power, kW | 30 |

| Total number of coordinates | 5 |

| Number of simultaneously controlled coordinates | 3 |

0000The special feature of the machine layout is a longitudinally movable gantry and a fixed table, on the working surface of which the workpieces are mounted. The gantry moves on roller guides mounted on freestanding beds and carries a vertical milling and drilling headstock with a vertical-moving slider with built-in main motion drive. The headstock is equipped with extension and universal milling heads for machining upper and side planes of workpieces.

0000The discrete rotation of the universal milling head around two axes (vertical and 45°) is automatically controlled by the CNC.

0000The machine offers positioning accuracy of 30 µm over a length of 4,000 mm and production flexibility to incorporate new technologies for machining virtually any part on a fixed table.

Innovative solutions

0000Development on the basis of the machine mod. MS21G25MF4 of the new range of portal machines of “Gentry” type with the range of main motion drive power 30 – 40 kW and a wide range of coordinate movement lengths:

- gantry (X coordinate) – from 5,000 to 20,000 mm;

- headstock (Y coordinate) – from 1,500 to 4,500 mm;

- crawler (Z coordinate) – from 800 to 1 500 mm;

- increasing the feed rate to 15 m/min.

0000The machine is equipped with various milling heads of universal and special purpose (straight and angular), the system of control of the processed part is applied

OUR CONTACTS

-

Минск, ул. Ленина, 46

Минск, ул. Ленина, 46

-

+375(17) 224 59 22

+375(17) 224 59 22

-

mail@mzor.by

mail@mzor.by

CONTACT FORM

If you have any questions, you can contact us using the contact form below.