JSC “MZOR”, specializes in the manufacture of heavy machine tools for machining large-sized body parts of high complexity and has the technological capability to perform:

I. MACHINING OF ROUND, FLAT, BASE AND BODY PARTS OF ANY METALS AND ALLOYS WITH THE FOLLOWING TYPES OF WORK:

1. turning the largest diameter of the workpiece: above the bed 900 mm, above the slide 650/490 mm;

largest distance between centers 4 000 mm.

2. Circular grinding

the largest diameter of the workpiece is 400 mm;

maximum length of the workpiece 3000 mm.

3. Toothgrinding

the smallest and the largest diameter of the workpiece 34 ÷ 700 mm;

module 1.5 ÷ 7;

number of teeth 16 ÷ 240.

4. lathe and carousel

the largest diameter of the workpiece to be machined with the side slide is 1 600 mm;

maximum height of the workpiece 1 400 mm.

5. Horizontal boring machine

maximum boring depth with spindle 1 500 mm;

vertical movement of the spindle headstock on the stand 3,000 mm;

horizontal movement of the rack on the bed 8 000 mm.

6. Planing

width 1,600 mm;

length 14,000 mm;

height 1,750 mm.

7. Milling

largest workpiece width 4 500 mm;

the longest workpiece length is 14,000 mm;

maximum height of the workpiece 3 200 mm.

8. Longitudinal grinding

largest dimensions of machined surfaces: width 2,200 mm, height 2,000 mm, length 12,000 mm;

distance between posts 2 680 mm.0000

II. OTHER SERVICES

1. Manufacturing of model kits for foundry production

2. Diagnostics and repair of electrical equipment of machine tools.

3. Diagnostics and repair of various CNC systems and CNC machines.

4. Repair of electric drives EPU, BTU, etc.

5. Dismantling of electrical equipment and other electrical work.

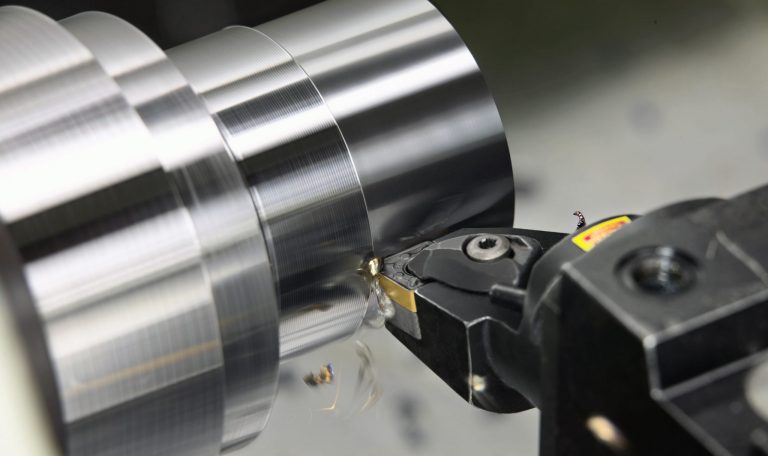

A CNC lathe “STX 310 ECOLINE” manufactured by DECKEL MAHO GILDEMISTER, Germany, is installed at the production facilities of “Stankodetal”. This machine is equipped with a turret with a 12 position CNC driven tool.

A CNC lathe “STX 310 ECOLINE” manufactured by DECKEL MAHO GILDEMISTER, Germany, is installed at the production facilities of “Stankodetal”. This machine is equipped with a turret with a 12 position CNC driven tool.

Processing range:

maximum diameter above the bed – 330 mm

maximum machining diameter – 200 mm.

transverse stroke (X) – 182.5 mm.

longitudinal stroke (Z) – 455 mm.

maximum speed – 4 500 min-1

The machine can turn parts of bodies of rotation such as shaft, axle, flange, bushing, nut, etc. in the range indicated above.

The integrated management system “Design, production, repair, modernization of machine tools and provision of services for metal products manufacturing” in JSC “MZOR” meets the requirements of STB ISO 9001-2015.

OUR CONTACTS

-

Минск, ул. Ленина, 46

Минск, ул. Ленина, 46

-

+375(17) 224 59 22

+375(17) 224 59 22

-

mail@mzor.by

mail@mzor.by

CONTACT FORM

If you have any questions, you can contact us using the contact form below.