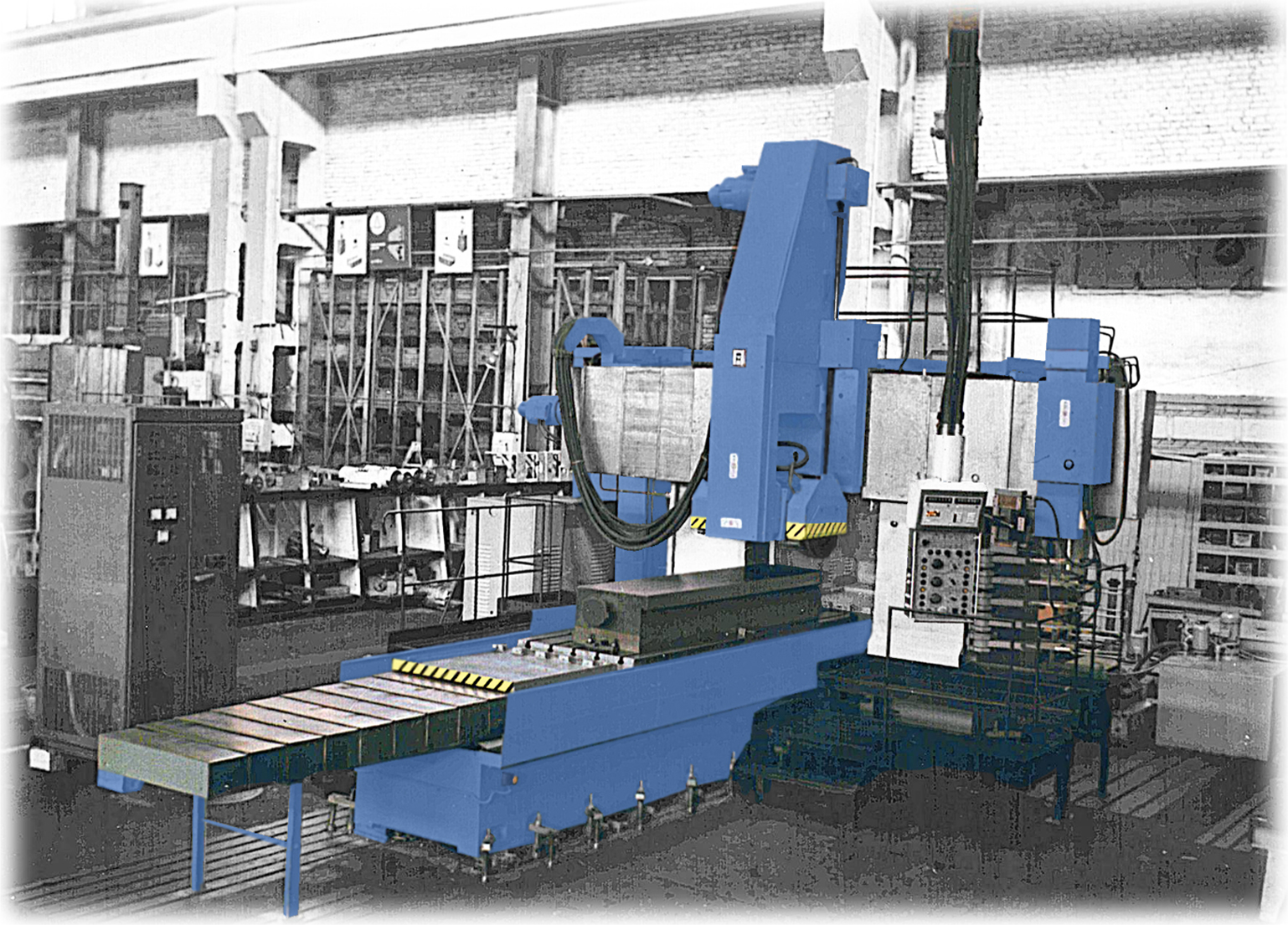

Special longitudinal grinding machine with autonatic tool change mod. МS316F10P-06, МS358F10

Machine features:

— The machine is designed for grinding and milling with tools equipped with super hard materials, guide and base surfaces of machine tool parts and other machines with increased requirements and accuracy and roughness of processing;

— In one installation, it is possible to process three sides of the part — the top and two side ones;

— Hardened steel overhead guide rails, headstock slider, caliper, straightening device;

— Guides of the table, carriages of the support and slider of the straightening device are reinforced with fluoroplastic;

— Guides for rolling of the headstock slider and combined sliding-rolling of the carriage of the support;

— Ball screws for horizontal and vertical movement of the headstock;

— Main drive with frequency regulation.

| Parameter name | МS316F10P-06 | МS358F10 |

| The greatest mass of the workpiece to be installed (taking into account the mass of the fixing elements), kg | 12 000 | 6 300 |

| Swivel head spindle diameter according to GOST 2323-76, mm | 100 | 100 |

| The shape and size of the headstock grinding wheels | PP 600х80х305

PV 600х100х305 ChK 150х40х32 ChK150х50х32 |

PP 600х80х305

PV 600х100х305 ChK 150х40х32 ChK150х50х32 |

|

Grinding depth, μm

|

2; 2,5; 3; 4; 5; 6; 8;

10; 12; 16; 20; 25; 30; 40; 50 |

2; 2,5; 3; 4; 5; 6; 8;

10; 12; 16; 20; 25; 30; 40; 50 |

| Table working surface dimensions, mm

width length |

1 600 6 000 |

1 000 3 150 |

| Overall dimensions of the machine without separately located units, mm

length width height |

19 000 7 200 6 300 |

12 150 6 200 5 600 |