Machine features:

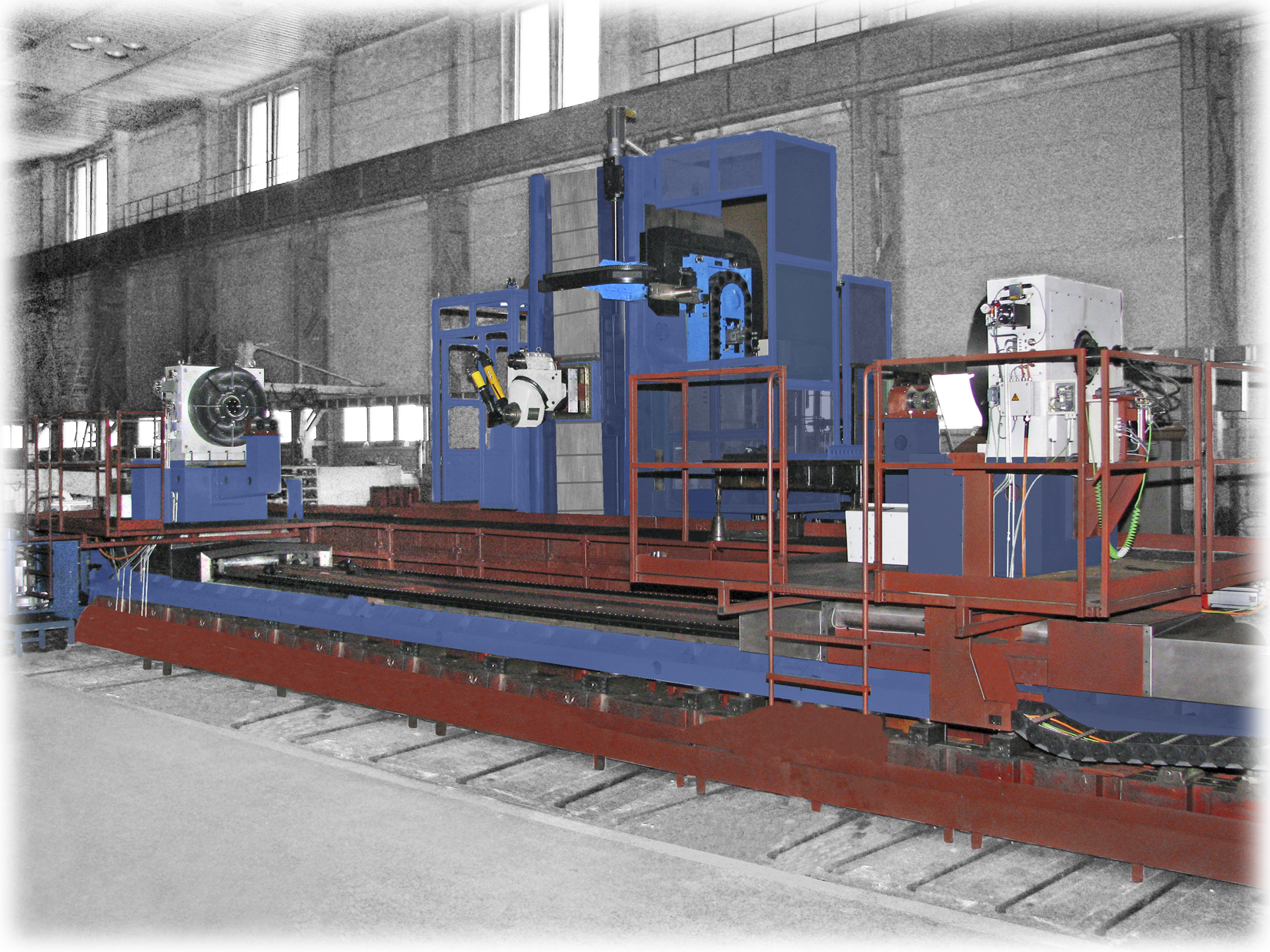

— A special technological complex for processing large-sized items made of composite materials;

— The complex includes: a milling module with a horizontal milling and boring movable stand, a universal milling head;

— Device for fixing parts and giving them rotation;

— The peculiarity of the layout of the complex is a free-standing, longitudinally moving rack and a lathe module, which has a movable and fixed headstock.

|

Parameter name |

МSP6403МF4-10R1 |

| The largest outer diameter of the workpiece, mm | 2 150 |

| The smallest inner diameter of the workpiece, mm | 500 |

| Maximum length of the workpiece to be installed, mm | 9 000 |

| The smallest length of the workpiece to be installed, mm | 600 |

| Largest movement, mm:

racks along the «X» axis headstock along the «Y» axis slider along the «Z» axis |

10 500 2 000 1 250 |

| The limits of the spindle rotation frequency of the universal milling head, rpm | 20…2 000 |

| The greatest torque on the spindle, N * m | 1 000 |

| Main drive power, kW | 22 |

| Discreteness of rotation of the universal milling head | 50 |

| Rotation frequency limits of the workpiece, rpm | 2…30 |

| The greatest movement of the tailstock of the turning module, mm | 9 200 |

| Maximum speed of setting movement of the tailstock of the turning module, m / min | 10 |

| The greatest weight of the processed product in special faceplates, kg | 2 500 |

| Complex weight, no more, kg | 80 000 |

| Overall dimensions, mm

length width height |

18 400 9 810 5 400 |