MZOR OJSC specializes in the manufacture of heavy machines for machining of large-sized body parts of a high degree of complexity and has the technological capabilities to perform:

I. Machining of round, flat, base and body parts made of any metals and alloys with the following types of work::

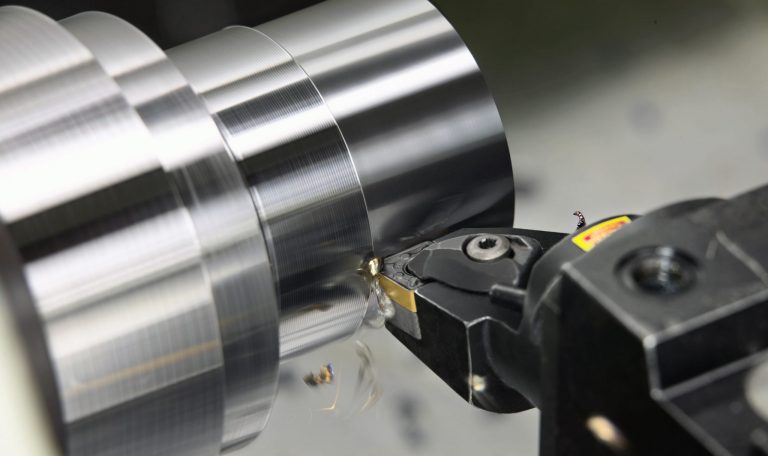

1. Lathe work

1. Lathe work

- the largest diameter of the workpiece: above the base 900 mm, above the tool box 650/490 mm;

- the largest distance between the centers 4 000 mm.

2. Circular grinding

- the largest diameter of the workpiece 300 mm;

- the largest length of the workpiece 3 000 mm

3. Gear grinding

- the smallest and largest diameter of the workpiece 34 ÷ 700 mm;

- modular unit 1,5 ÷ 7;

- number of gears 16 ÷ 240.

4. Turning-and-boring

- the largest diameter of the workpiece with side tool box 2 500 mm;

- the largest height of workpiece 1 600 mm.

5. Horizontal boring

- maximum depth of boring with a spindle 2 500 mm;

- vertical movement of the spindle headstock on the column 3 150 mm;

- horizontal movement of the column along the base 8 000 mm.

6. Planing

- width 1 600 mm;

- length 14 000 mm;

- height 1 750 mm.

7. Milling

- the largest width of the workpiece 4 500 mm;

- the largest length of the workpiece 14 000 mm;

- the largest height of the workpiece 3 200 mm.

8. Longitudinal grinding

- the largest dimensions of the machined surfaces: width 2 200 mm, height 2 000 mm, length 12 000 mm;

- distance between the columns 2 680 mm.

0000

0000II. Other services

- Production of model sets for foundry production.

- Diagnostics and repair of electrical equipment of machines.

- Diagnostics and repair of various CNC systems and machines with CNC systems.

- Repair of electric drives of electric starting devices, remote control units, etc.

- Disassembling of electrical equipment and other electrical work.

A CNC lathe СТХ 310 ECOLINE manufactured by DECKEL MAHO GILDEMISTER group corporation, Germany, is installed on the production areas of Stankodetal. This machine is equipped with a turret head with a CNC drive tool for 12 positions.

A CNC lathe СТХ 310 ECOLINE manufactured by DECKEL MAHO GILDEMISTER group corporation, Germany, is installed on the production areas of Stankodetal. This machine is equipped with a turret head with a CNC drive tool for 12 positions.

Machining range:

- maximum diameter above the base – 330 mm;

- maximum machining diameter – 200 mm;

- transverse movement (X) – 182.5 mm;

- longitudinal movement (Z) – 455 mm;

- maximum number of rotations – 4 500 min-1

0000

With the help of the machine, turning machining of rotation bodies parts of types shaft, coupling, sleeving, nut, etc., is possible in the range specified above.

At MZOR OJSC, the integrated management system “Design, production, repair, upgrading of machines and provision of services for the manufacture of metal products” complies with the requirements of STB ISO 9001-2015.